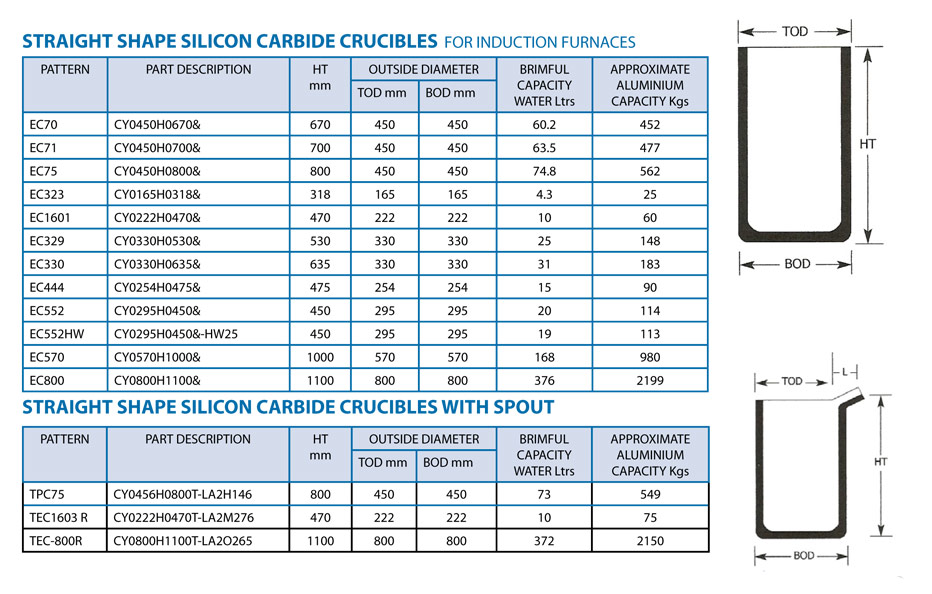

We offer high quality of Crucible. They are manufactured precisely to the specifications forwarded to us by the clients. Manufactured in accordance with set industrial standards, and are known for their features such as superior strength, fine finish, durable performance.

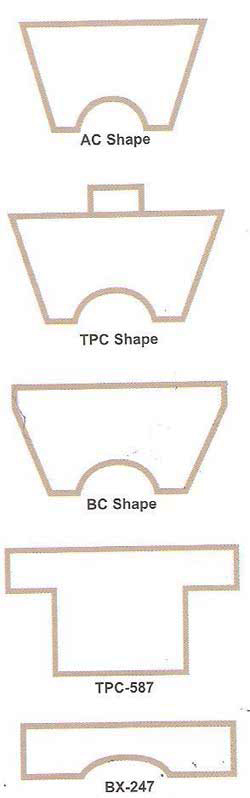

| STANDS | ||||||||

| SR.No | PATTERN | TOP OD MM |

BOTTOM OD mm | HEIGHT mm | AC | BC | TPC | SPIGOT |

| 1 | XRC 122/1 | 285 | 230 | 125 | 160, 175, 180, 200, 205, 225, 230, 250, 255, 330, 350, 365 | 175400 | ||

| 2 | XRC 122/1(S) | 285 | 230 | 125 | 843500 | Y | ||

| 3 | XRC 132/1 | 310 | 250 | 125 | 300, 355, 375, 400, 405, 410 | 166, 167, 168, 171 | 287355 | |

| 4 | XRC 132/1 (S) | 310 | 250 | 125 | 740, 355, 843, 10, 12, 982, 983 | Y | ||

| 5 | XRC 132/3 (Ss) | 310 | 250 | 300 | 740, 355, 843, 10, 12, 982, 983 | Y | ||

| 6 | XRC 132/4 (S) | 310 | 250 | 175 | 740, 355, 843, 10, 12, 982, 983 | Y | ||

| 7 | XRC 132/5 (S) | 310 | 275 | 75 | 740, 355, 843, 10, 12, 982, 983 | Y | ||

| 8 | XRC 202/1 | 360 | 250 | 125 | 500, 510, 610, 555 | 202, 302, 401, 402 | 387, 412 | |

| 9 | XRC 202/1 (S) | 360 | 250 | 125 | 412, 89 | Y | ||

| 10 | XRC 202/2 | 360 | 250 | 175 | 500, 510, 610, 555 | 202, 302, 401, 402 | 387, 412, 89 | |

| 11 | XRC 202/2 (S) | 360 | 250 | 175 | 387, 412, 89 | Y | ||

| 12 | XRC 202/3 (S) | 360 | 250 | 225 | 500, 510, 610, 555 | 202, 302, 401, 402 | ||

| 13 | XRC 202/3 (S) | 360 | 250 | 225 | 387, 412, 89 | Y | ||

| 14 | XRC 202/4 | 360 | 250 | 150 | 500, 510, 610, 555 | 202, 302, 401, 402 | ||

| 15 | XRC 247 | 425 | 425 | 115 | 247, 263, 700 | |||

| 16 | XRC 247/50 | 425 | 425 | 50 | 247, 263, 700 | |||

| 17 | XRC 587 | 425 | 300 | 215 | 588, 651 | |||

| 18 | XRC 360/50 | 360 | 360 | 50 | ||||

| 19 | XRC 310/50 | 360 | 360 | 50 | ||||

| 20 | XRC 804 | 350 | 350 | 120 | 847 | |||

| 21 | XRC 2471 | 425 | 425 | 100 | 247, 263, 264 | |||

| 22 | XRC 2474 | 425 | 425 | 150 | 247, 263, 264 | |||

| 23 | XRC 2472 | 425 | 425 | 200 | 247, 263, 264 | |||

Features:

- Stand of different heights also can be made available on order

- Stand with spigot also available for TPC models having recess.

| RED DIAMOND “SIGMA” AI SHAPE (SMALL) (ISOSTATIC CRUCIBLES) | ||||||

| SR.No. | Type | Size | Height mm | TOP D mm | Bottom D mm | Brimful Capacity Liters |

| 1 | AI | 6/0 | 29 | 25 | 19 | 0.004 |

| 2 | AI | 5/0 | 35 | 32 | 25 | 0.009 |

| 3 | AI | 4/0 | 51 | 41 | 27 | 0.022 |

| 4 | AI | 3/0 | 54 | 48 | 32 | 0.036 |

| 5 | AI | 2/0 | 57 | 52 | 36 | 0.041 |

| 6 | AI | 1/0 | 72 | 60 | 42 | 0.069 |

| 7 | AI | 1/4 | 75 | 65 | 45 | 0.092 |

| 8 | AI | 1/2 | 80 | 74 | 50 | 0.133 |

| 9 | AI | 0.5 | 80 | 74 | 50 | 0.160 |

| 10 | AI | 1 | 95 | 92 | 65 | 0.280 |

| 11 | AI | 1.1 | 97 | 79 | 55 | 0.177 |

| 12 | AI | 1.2 | 100 | 80 | 54 | 0.187 |

| 13 | AI | 1.4 | 110 | 94 | 54 | 0.255 |

| 14 | AI | 1.9 | 125 | 104 | 65 | 0.405 |

| 15 | AI | 2 | 120 | 110 | 75 | 0.55 |

| 16 | AI | 2.1 | 110 | 102 | 65 | 0.366 |

| 17 | AI | 3 | 135 | 120 | 80 | 0.74 |

| 18 | AI | 3.1 | 130 | 110 | 70 | 0.534 |

| 19 | AI | 4 | 155 | 140 | 100 | 1.26 |

| 20 | AI | 4.1 | 140 | 115 | 75 | 0.655 |

| 21 | AI | 4.2 | 141 | 115 | 75 | 0.596 |

| 22 | AI | 5 | 165 | 140 | 100 | 1.37 |

| 23 | AI | 5.1 | 150 | 125 | 85 | 0.859 |

| 24 | Al | 85 | 430 | 325 | 210 | 16.54 |

| 25 | Al | 86 | 410 | 330 | 227 | 18.06 |

| 26 | Al | 90 | 405 | 350 | 240 | 20.64 |

| 27 | Al | 100 | 410 | 350 | 240 | 20.96 |

| 28 | Al | 110 | 420 | 350 | 240 | 21.75 |

| 29 | Al | 120 | 435 | 350 | 240 | 22.97 |

| 30 | Al | 135 | 450 | 380 | 240 | 25.23 |

| 31 | Al | 150 | 475 | 380 | 240 | 26.63 |

| 32 | Al | 151 | 485 | 380 | 240 | 27.19 |

| 33 | Al | 180 | 500 | 380 | 240 | 28.46 |

| 34 | Al | 185 | 500 | 430 | 260 | 33.84 |

| 35 | Al | 195 | 500 | 410 | 295 | 35.58 |

| 36 | Al | 200 | 540 | 430 | 260 | 37.63 |

| 37 | Al | 225 | 565 | 430 | 260 | 40.02 |

| 38 | Al | 250 | 590 | 430 | 260 | 42.41 |

| 39 | Al | 255 | 545 | 440 | 295 | 48.36 |

| 40 | Al | 260 | 610 | 430 | 260 | 44.33 |

| 41 | Al | 280 | 635 | 430 | 260 | 47.6 |

| 42 | Al | 300 | 585 | 475 | 320 | 55 |

| 43 | Al | 305 | 540 | 440 | 315 | 44.55 |

| 44 | Al | 325 | 600 | 475 | 320 | 56.65 |

| 45 | Al | 326 | 600 | 490 | 280 | 59.19 |

| 46 | Al | 350 | 640 | 475 | 320 | 61.65 |

| 47 | Al | 351 | 640 | 490 | 280 | 64.26 |

| 48 | Al | 351.2 | 670 | 490 | 280 | 68.5 |

| 49 | Al | 354 | 600 | 535 | 315 | 69.401 |

| 50 | Al | 355 | 600 | 560 | 360 | 75.83 |

| 51 | Al | 400 | 660 | 564 | 360 | 86.63 |

| 52 | Al | 401 | 660 | 540 | 315 | 79.398 |

| 53 | Al | 402 | 620 | 515 | 360 | 72.82 |

| 54 | Al | 405 | 680 | 540 | 315 | 82.56 |

| 55 | Al | 406 | 680 | 515 | 360 | 82.3 |

| 56 | Al | 450 | 705 | 564 | 360 | 95.39 |

| 57 | Al | 500 | 720 | 564 | 360 | 97.42 |

| 58 | Al | 501 | 720 | 545 | 315 | 89.063 |

| 59 | Al | 502 | 660 | 515 | 360 | 78.77 |

| 60 | Al | 510 | 740 | 545 | 315 | 93.77 |

| 61 | Al | 525 | 740 | 564 | 360 | 101.28 |

| 62 | Al | 550 | 760 | 564 | 360 | 104.62 |

| 63 | Al | 551 | 760 | 545 | 315 | 96.36 |

| 64 | Al | 552 | 720 | 520 | 360 | 88.08 |

| 65 | Al | 600 | 810 | 564 | 360 | 113.61 |

| 66 | Al | 601 | 810 | 548 | 315 | 104.79 |

| 67 | Al | 602 | 810 | 520 | 360 | 101.61 |

Notes:

- The dimensions shown are nominal and subject to normal manufacturing tolerances.

- Our curcibles are recommended for non- ferrous alloys except those containing more than 30% of Nickel, Chromium or Iron.

- Working capacities are based on Brass Specific Gravity 8.35 and Aluminum Specific Gravity 2.7 and 90% of Brimful Capacity approx.